Stainless & Nickel Products

Duplex Stainless Steels have a microstructure that contains each ferrite and austenite. When Duplex Stainless Steel is melted, it solidifies from the liquid phase to a very ferritic structure. As the fabric cools, approximately half of it adjustments to an austenitic structure. The result’s an alloy with a microstructure of roughly 50% austenite and 50% ferrite.

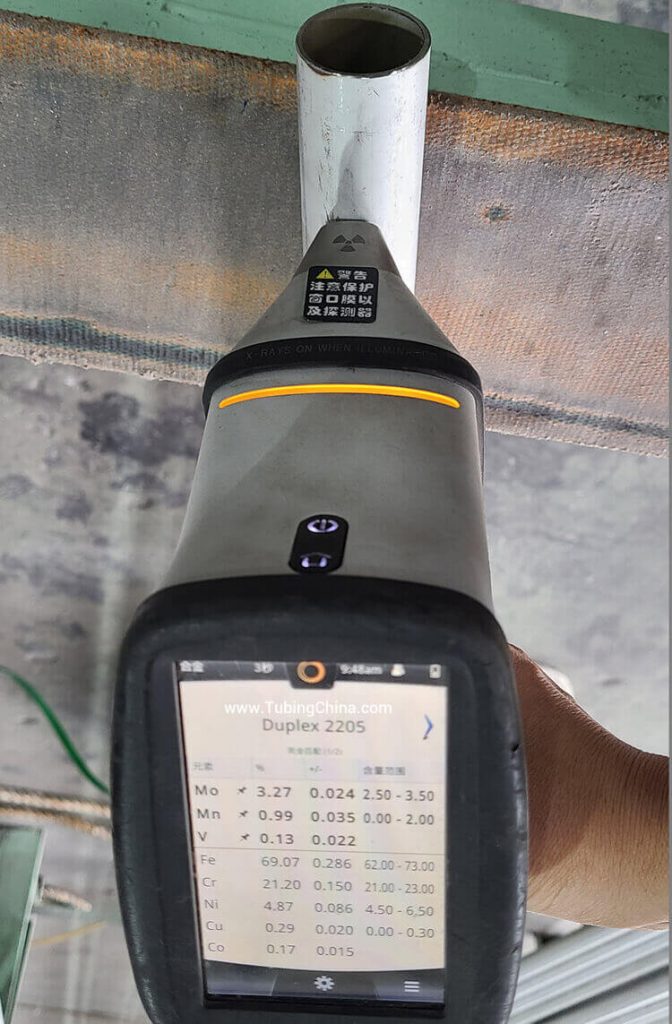

Duplex S31803 And Super Duplex S32750 Performance

What is the difference between duplex and stainless steel?

Introduction. Stainless steel Super Duplex 2507 is designed to handle highly corrosive conditions and situations were high strength is required. High molybdenum, chromium and nitrogen content in Super Duplex 2507 help the material withstand pitting and crevice corrosion.

Less heat transfer surface space is required to perform the identical responsibility. Duplex stainless steels have decrease nickel and molybdenum contents than their austenitic counterparts of comparable corrosion resistance. Due to the lower alloying content, duplex stainless steels may be decrease in price, particularly in instances of excessive alloy surcharges. Additionally, it might usually be possible to reduce the section thickness of duplex chrome steel, due to its elevated yield energy compared to austenitic stainless-steel. The mixture can lead to significant value and weight savings compared to an answer in austenitic stainless steels.

Our mainly stainless steel grade: ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

As with all corrosion-resistant alloys, duplex stainless steels can undergo corrosion when uncovered to suitably corrosive situations. As they include the next chromium content material than normal 3xx grades, their Pitting Resistance Equivalent Number (PREN) is larger, indicating elevated resistance to pitting corrosion.

- However, with increasing chloride contents, greater alloyed stainless steels similar to Type 2205 and tremendous austenitic and super duplex stainless steels are used.

- Stainless steels have a long historical past of utility involved with water as a result of their excellent corrosion resistance.

- Types 304 and 316 stainless steels are normal supplies of construction in touch with water.

- Applications include a spread of situations together with plumbing, potable water and wastewater treatment, desalination, and brine treatment.

- The similar material is used whereas manufacturing duplex stainless steel nevertheless the utilization ratio is totally different in both cases & change in ration ends in increased strength, & corrosion resistance.

- Alloy 2205 is a 22% Cr duplex stainless-steel, equipped in the answer annealed situation.

Ferralium® 255 – SD50 (super duplex 255) is a stainless-steel which is supplied within the hot worked and annealed situation. It achieves larger strengths than most different stainless steels and alternative corrosion resistant alloys, providing the potential to reduce section size and due to this fact weight and price. Stainless metal is now used as one of the supplies for tramlinks, together SA240 316 Stainless steel plate with aluminium alloys and carbon metal. Duplex grades are usually most popular because of their corrosion resistance and better energy, permitting a reduction of weight and a long life in maritime environments. The properties of duplex stainless steels are achieved with an general decrease alloy content than related-performing tremendous-austenitic grades, making their use price-efficient for a lot of applications.

However, to be able to retain the favourable stability of austenitic and ferritic microstructures, it is also necessary to increase the content material of nickel and different elements, which also will increase the cost. Ferralium® 255 – 3AF is a brilliant duplex stainless steel equipped in the scorching worked, annealed and aged situation.

By subjecting the product to an additional ageing process, it’s potential to additional enhance the tensile strength of the product while retaining its excessive ranges of ductility. Alloy 316L is an austenitic stainless-steel provided within the sizzling labored and annealed situation. The addition of Mo offers the product with much improved corrosion resistance compared with Alloy 304, significantly with respect to pitting and crevice corrosion in chloride environments. When contemplating Duplex Stainless Steel for Heat Exchangers, usually there may be much more benefit. The lower nickel content material of the Duplex grades means a better thermal conductivity as compared to the austenitic equal grade.

What is Super Duplex material?

Stainless Steels. Duplex stainless steels are based around a composition of 22% chromium, whereas super duplex stainless steels are based around a composition of 25% chromium. By increasing the chromium content, the level of pitting corrosion resistance is also increased.

Please see our product range and grade.

Duplex alloys have higher power and better stress corrosion cracking resistance than most austenitic alloys and larger toughness than ferritic alloys, particularly at low temperatures. Duplex and super duplex belong to a household of stainless steels that are characterised by a mixture of simple fabrication, excessive energy and glorious corrosion resistance. This group of materials is most just like ferritic and carbon metal, however it has some physical properties consistent with these found in austenitic stainless-steel. Duplex stainless steels are primarily based around a composition of 22% chromium, whereas super duplex stainless steels are primarily based round a composition of 25% chromium. By increasing the chromium content material, the level of pitting corrosion resistance can also be elevated.