Please see our product range and grade.

304l Dual Certified Stainless Steel

Stainless steel 304 alloy has a most operating temperature of about 870˚C. Stainless “H” grades have a minimal of .04% carbon and a most of .10% carbon. The greater carbon helps retain energy at extreme temperatures.

Other Examples Of Dual Certified Term

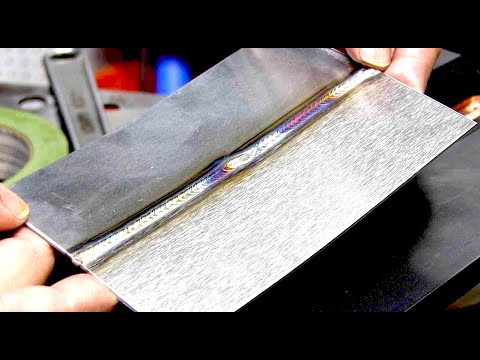

It does not require publish-weld annealing and so is extensively used in heavy gauge parts (over about 6mm). Grade 304H with its higher carbon content material finds application at elevated temperatures. The alloy can A240 304L Stainless steel plate be welded without a lot lack of corrosion resistance because of carbide precipitation and for certain applications the metal can be utilized within the as-welded condition.

- Due to the addition of molybdenum, grade 316 stainless steel is more corrosion resistant than related alloys, such as 304 chrome steel.

- This reduces pitting from chemical environments and allows grade 316 stainless steel to be used in extremely acidic and caustic environments that may otherwise eat away at the metal.

- Martensitic grades are primarily used the place hardness, strength, and put on resistance are required.

Mechanical Properties Of Stainless Steel 304

These grades are indicated by the letter “H” after the stainless grade quantity. The use of this designation could be when the top-use involves an extreme temperature setting. After being air stress tested, Rolex proceeds to check the water resistance of each and every Rolex Submariner and Deep Sea watch in actual water. Submariner watches are positioned in giant tubes which might be full of water to ensure that they are water-proof to 300 meters.

If you have ever noticed that metal on a Rolex watch looks different than other watches, it is because of 904L steel, and how Rolex has realized to work with it. – Ease of cleansing, ease of fabrication, beauty of look Grade 304L is the low carbon model of 304.

For use in the most corrosive environments nonetheless, the welded construction must be re-annealed. And neither are as sturdy as 317 and 317L, which have higher molybdenum content and are better for overall corrosion resistance. Each is barely totally different, and every is used for various functions. When it comes to providing chrome steel solutions, Marlin Steel relies on grade 316 stainless steel to fabricate its in-stock products and custom wire baskets. Grade 304 chrome steel is very distinctive for its high tensile energy of about 621 MPa (90 ksi).