1.4122 material chrome steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Known Tradenames:

With the advent of the microalloying management, this alloy is comparably priced with 310 stainless steel, but it delivers high energy properties similar to the higher nickel Inconel® 600-sequence materials. In addition to its superb oxidation resistance in air, Sandvik 253 MA can be highly proof against other atmospheres. The extremely protecting oxide layer makes it attainable to make use of this steel at excessive temperatures in atmospheres containing sulphur and different aggressive compounds. Sandvik 253 MA is commonly most well-liked instead of stainless chromium steels which have insufficient creep energy and structural stability. Furthermore, Sandvik 253 MA can very well take the place of higher alloyed supplies such as 25Cr/20Ni steels and Alloy 800H, or even Alloy 600 in sure cases.

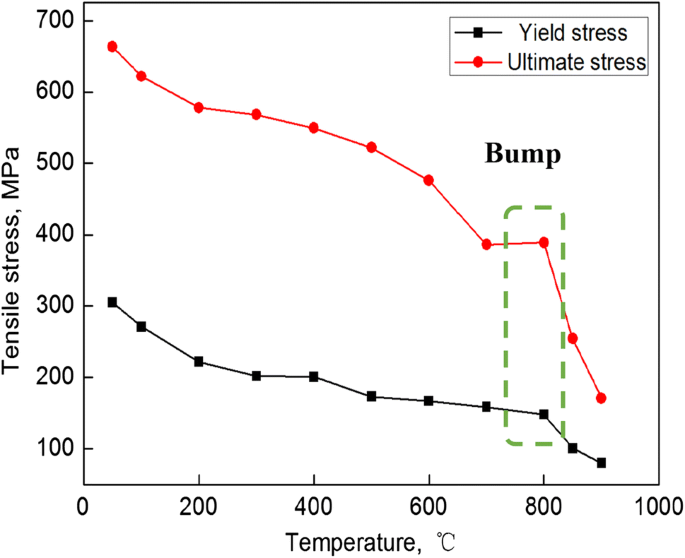

Recuperator tubes in a wide range of high-temperature corrosion resistant materials suitable for flue gas temperatures as much as 1300ºC (2370ºF). The temperature above which design calculations are primarily based on creep rupture energy instead of Rp0.2 proof energy, can be learn off from Fig. For Sandvik 253 MA this temperature is about 550°C (1020°F). 2 reveals the relationship between nominal stress and minimum creep fee, measured throughout testing under fixed load.

However, with positive feeds and sluggish speeds mixed with abundant slicing fluid this alloys tendency to work harden could also be minimized. 253MA incorporates pretty low nickel content material, which supplies it some benefit in decreasing sulphide atmospheres when compared to excessive nickel alloys and to Grade 310.

Our stainless production range

- Nitrogen, carbon and a dispersion of uncommon earth and alkali steel oxides combine to provide creep rupture energy similar to the nickel base alloys.

- 253 MA maintains its warmth resistant properties by advanced control of micro alloy additions.

- Stainless 253 MA is a lean austenitic heat resistant alloy with high strength and outstanding oxidation resistance.

- The use of uncommon earth metals in combination with silicon provides superior oxidation resistance up to 2000°F.

The inclusion of excessive silicon, nitrogen and cerium contents offers the steel good oxide stability, excessive elevated temperature power and wonderful resistance to sigma section precipitation. Sandvik 253 MA is extra resistant than the upper alloyed 25Cr/20Ni steels to combustion fuel assaults in cyclic conditions.

Under decreasing circumstances, nevertheless, the use of RA 253 MA in carburizing environments must be averted. Due to its lower nickel content, it is less proof against carburization than greater-nickel alloys such as RA 330.

Muffle tubes in a variety of high-temperature corrosion resistant supplies. The Sandvik program of muffle tubes consists of supplies appropriate for all sorts of protecting gases and environments, covering service situations as much as 1200ºC (2190ºF). A METAL SOURCE, LLC is a distributor of assorted 253 MA ® Alloy in any measurement or type. 253 MA ® Alloy is an Austenitic Chromium-Nickel steel that’s alloyed with Nitrogen and Rare Earth Metals. This alloy has been utilized in a variety of functions similar to warmth exchangers, boiler nozzles, petrochemical and refinery tube hangers.

Even although sizzling tensile energy is reported up to 2200˚F (1204˚C), the loss of oxidation resistance at 2000˚F makes its practical use restrict 2000˚F (1093˚C) in oxidizing environments. Thermocouple safety tubes (pyrometer protection tubes) in a wide range of high-temperature corrosion resistant supplies. The Sandvik program contains supplies suitable for all sorts of defending gases and environments overlaying operating temperatures as much as 1200ºC (2190ºF).

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean