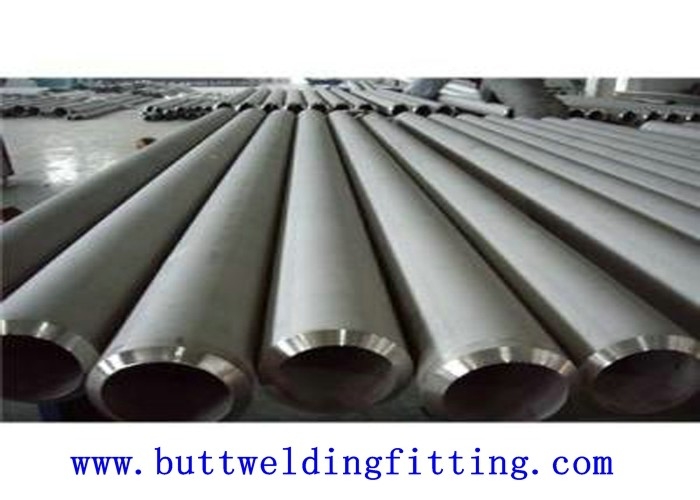

1 inch stainless tube

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

This restores the influence power of the weld steel to the identical degree as that of the mother or father metal. Being a two-part (austenitic-ferritic) materials, Sandvik SAF 2205™ will current a different tool put on profile from that of single part steels of types ASTM TP304/304L and TP316/316L. The slicing pace should, therefore, be decrease than that recommended for ASTM 304/304L and 316/316L. It is beneficial that a harder insert grade is used than when machining austenitic stainless-steel, e.g.

The impression energy of welded Sandvik SAF 2205™ can also be good, regardless of the influence energy values within the as-welded situation being slightly decrease than for weld-free materials. Tests show that the influence energy of fabric, welded by means of fuel-shielded arc welding, is sweet in each the weld steel and the heat-affected zone down to -50°C (-fifty eight°F). At this temperature, the impact power is a minimal of 27 J (20 ft lb). If very high influence power calls for are made on the weld metallic at low temperatures, answer annealing is really helpful.

The welding of 2205 is not tough, however it’s essential to design welding procedures that lead to a favorable section stability after welding and will avoid precipitation of detrimental intermetallic or nonmetallic phases. Alloy 2205 duplex stainless-steel plate combines high energy and excessive corrosion resistance to produce excessive corrosion fatigue energy. Applications during which processing tools is subject to each an aggresively corrosive enviroment and to cycle loading can benefit from the properties of 2205 duplex stainless steel plate.

Corrosion Resistance

- Duplex 2205 is a two-part, ferritic, austenitic 22% chromium, three% molybdenum, 5 to 6% nickel alloyed stainless-steel.

- It additionally demonstrates good fatigue strength, in addition to excellent resistance to stress corrosion cracking, crevice, pitting, erosion, and general corrosion in severe environments.

- It is the most broadly used duplex stainless steel grade and is characterized by high yield power, double that of the usual austenitic stainless-steel grades.

- This ends in a microstructure that offers corrosion properties and toughness roughly equal to that of the father or mother metallic.

Our stainless production range

This grade is immune to chloride stress corrosion cracking (SCC) at temperatures of 150°C. Grade 2205 stainless steels are apt replacements to austenitic grades, especially in untimely failure environments and marine environments. Although 2205 has good excessive temperature oxidation resistance, this grade, like different duplex stainless steels, suffers from embrittlement if held for even quick instances at temperatures above 300oC. If embrittled this will solely be rectified by a full resolution annealing therapy.

The UNS designation for SAF 2205 is S31803/S32205 and the EN metal no. is 1.4462. SAF 2205 or Duplex 2205 is usually used as an alternative to costly 904L stainless-steel owing to comparable properties however cheaper ingredients. Duplex chrome steel is out there in a number of varieties like bars, billets, pipes, tubes, sheets, plates and even processed to fittings and flanges. Alloy 2205 duplex stainless-steel plate possesses good weldability. The objective of welding 2205 is that the weld steel and warmth-affected zone (HAZ) retain the corrosion resistance, energy, and toughness of the bottom metal.

Resistance to emphasize corrosion cracking (SCC) in neutral chloride solutions with an oxygen content of about 8 ppm. Laboratory results for Sandvik SAF 2205™ of constant load specimens loaded to the proof energy on the test temperature. SAF 2205, also called Sandvik SAF 2205, is a Sandvik-owned trademark for a 22Cr duplex (ferritic-austenitic) chrome steel. The nominal chemical composition of SAF 2205 is 22% chromium, 5% nickel, three.2% molybdenum and other alloying parts such as nitrogen and manganese.

Possible Alternative Grades

This combination of properties can mean some compromise in comparison with pure austenitic and pure ferritic grades. Sandvik SAF 2205™ possesses larger energy and higher corrosion resistance than odd austenitic stainless steels. Consequently, Sandvik SAF 2205, has significantly better fatigue strength under corrosive circumstances than such steels.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean