1.4404 aisi 316l stainless steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

The minimal 10.5% chromium in stainless steels offers resistance to roughly seven-hundred °C (1,300 °F), whereas sixteen% chromium provides resistance up to roughly 1,200 °C (2,200 °F). Type 304, the most typical grade of chrome steel with 18% chromium, is immune to approximately 870 °C (1,600 °F).

Also generally known as “marine grade” stainless steel due to its elevated resistance to chloride corrosion compared to kind 304. SS316 is commonly used for building nuclear reprocessing vegetation. Most watches that are made of stainless-steel are manufactured from this grade. Rolex is an exception in that they use Type 904L.

Other gases, similar to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault stainless-steel. Resistance to different gases relies on the kind of gasoline, the temperature, and the alloying content material of the stainless steel.

Chanson,TISCO,BAOSTEEL,POSCO,JISCO,LISCO

Our stainless production range

The most typical electrolyte is water, ranging from freshwater to seawater. When a galvanic couple types, one of the metals within the couple turns into the anode and corrodes faster than it would alone, while the opposite turns into the cathode and corrodes slower than it would alone.

- Type 304, the most typical grade of stainless-steel with 18% chromium, is immune to approximately 870 °C (1,600 °F).

- The minimum 10.5% chromium in stainless steels provides resistance to roughly 700 °C (1,300 °F), while 16% chromium supplies resistance as much as roughly 1,200 °C (2,200 °F).

- Other gases, similar to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, also attack chrome steel.

- Resistance to other gases depends on the kind of gas, the temperature, and the alloying content material of the chrome steel.

How do you mirror stainless steel?

Both steels are durable and provide excellent resistance to corrosion and rust. 304 stainless steel is the most versatile and widely used austenitic stainless steel in the world, due to its corrosion resistance. If your application uses milder acids or does not contain salt exposure, stainless 304 is perfect.

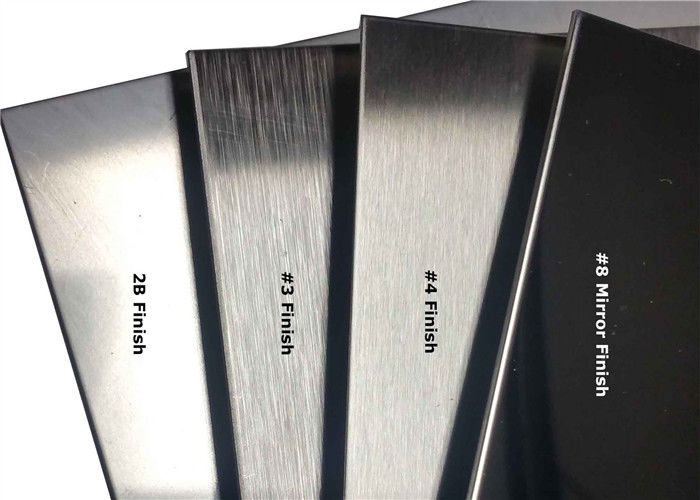

Standard Finishes

Austenitic stainless steel is the biggest household of stainless steels, making up about two-thirds of all chrome steel manufacturing (see manufacturing figures beneath). They possess an austenitic microstructure, which is a face-centered cubic crystal structure. Thus, austenitic stainless steels are not hardenable by warmth remedy since they possess the same microstructure at all temperatures. The second most common grade (after 304); for food and surgical chrome steel uses; Alloy addition of molybdenum prevents particular types of corrosion.

The ensuing surface accommodates a dark non-uniform appearance the place surface chromium has been lost, and the expected level of corrosion resistance has been achieved. A No. 1 finish could comprise shiny spots have been surface imperfections had been eliminated by grinding. It is generally used in industrial applications, similar to equipment for elevated temperature service. Stainless steel is now used as one of the materials for tramlinks, together with aluminium alloys and carbon metal. Duplex grades are usually most popular thanks to their corrosion resistance and higher energy, permitting a reduction of weight and an extended life in maritime environments.

Uniform Corrosion

In addition, as iron oxide occupies a bigger volume than the original metal, this layer expands and tends to flake and fall away, exposing the underlying steel to additional attack. This passive film prevents further corrosion by blocking oxygen diffusion to the metal floor and thus prevents corrosion from spreading into the majority of the metallic. This film is self-repairing, even when scratched or briefly disturbed by an upset condition in the surroundings that exceeds the inherent corrosion resistance of that grade.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean