1.4021 stainless steel 316

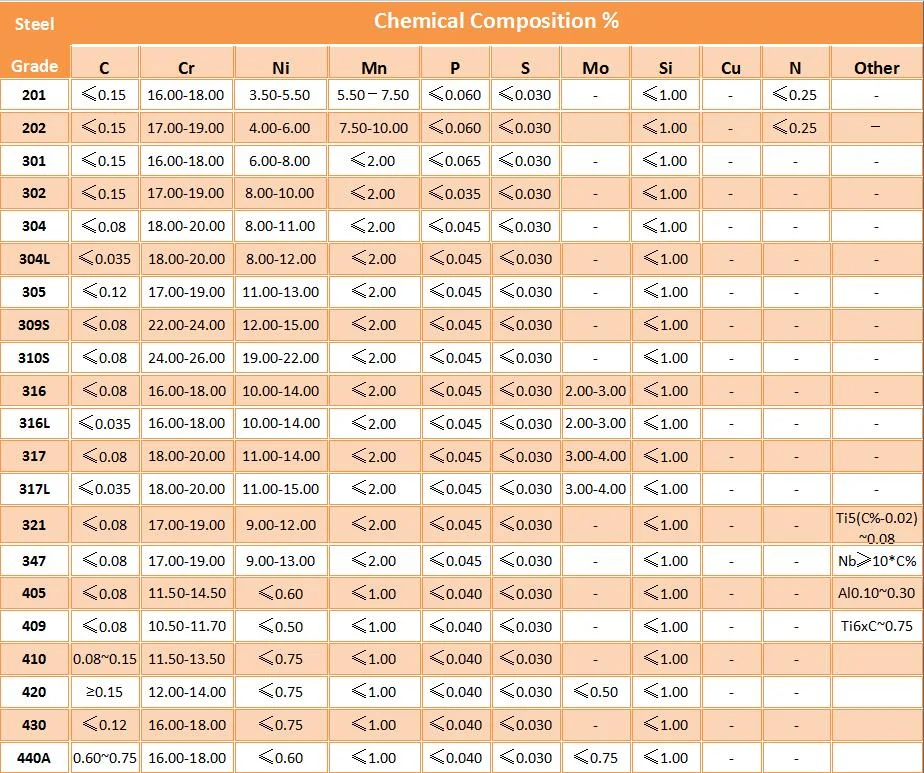

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

This passive film prevents further corrosion by blocking oxygen diffusion to the metal floor and thus prevents corrosion from spreading into the majority of the metal. This movie is self-repairing, even when scratched or temporarily disturbed by an upset condition within the environment that exceeds the inherent corrosion resistance of that grade.

Grade 316 is a well-liked alloy of stainless steel with a melting vary of 2,500 °F – 2,550 °F (1,371 °C – 1,399 °C). As an austenitic chrome steel alloy, it has qualities corresponding to excessive energy, corrosion resistance, and high concentrations of chromium and nickel. The alloy has a tensile strength of 579 MPa (eighty four ksi) and a maximum use temperature of round 800˚C (1,472˚F). Stainless steel stays stainless, or doesn’t rust, due to the interplay between its alloying elements and the setting.

At elevated temperatures, all metals react with hot gases. The commonest high-temperature gaseous mixture is air, of which oxygen is the most reactive element.

Do magnets stick to 304 stainless steel?

The 2 main types of stainless steel used for exhaust parts are 304 and 409. 304 stainless steel contains a much higher percentage of chromium and nickel. This makes it much more resistant to rust. 409 stainless steel is still more rust-resistant than Aluminized Steel.

What Is The Difference Between 304 And 409 Stainless Steel?

- Stainless steels have an extended historical past of software in contact with water as a result of their wonderful corrosion resistance.

- Applications embody a spread of circumstances together with plumbing, potable water and wastewater remedy, desalination, and brine remedy.

- Types 304 and 316 stainless steels are standard materials of development in contact with water.

Our stainless production range

Stainless metal incorporates iron, chromium, manganese, silicon, carbon and, in many circumstances, vital amounts of nickel and molybdenum. These parts react with oxygen from water and air to form a really skinny, stable film that consists of such corrosion products as steel oxides and hydroxides.

Duplex grades tend to be most well-liked thanks to their corrosion resistance and higher strength, permitting a discount of weight and a long life in maritime environments. The ease of welding largely is dependent upon the type of chrome steel used.

Austenitic stainless steels are the easiest to weld by electrical arc, with weld properties similar to these of the bottom metal (not cold-worked). Post-weld heat remedy is nearly all the time required while preheating before welding can also be necessary in some circumstances. The invention of chrome steel adopted a series of scientific developments, beginning in 1798 when chromium was first shown to the French Academy by Louis Vauquelin.

Which steel is better 304 or 202?

The presence of the stable film prevents additional corrosion by acting as a barrier that limits oxygen and water access to the underlying metal surface. In summary, stainless steel does not rust because it is sufficiently reactive to protect itself from further attack by forming a passive corrosion product layer.

Chromium plays a dominant function in reacting with oxygen to form this corrosion product film. In fact, all stainless steels by definition comprise a minimum of 10 p.c chromium. Stainless metal is now used as one of the supplies for tramlinks, together with aluminium alloys and carbon metal.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean