1.4034 aisi stainless-steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

The minimal 10.5% chromium in stainless steels offers resistance to roughly seven-hundred °C (1,300 °F), whereas 16% chromium supplies resistance up to approximately 1,200 °C (2,200 °F). Type 304, the most typical grade of stainless-steel with 18% chromium, is proof against approximately 870 °C (1,600 °F). Other gases, similar to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, also attack chrome steel. Resistance to other gases relies on the kind of gas, the temperature, and the alloying content material of the chrome steel. Stainless steels have an extended history of utility in contact with water due to their wonderful corrosion resistance.

Austenitic Stainless Steel

To keep away from corrosion in air, carbon steel is limited to roughly 480 °C (900 °F). Oxidation resistance in stainless steels increases with additions of chromium, silicon, and aluminium. Small additions of cerium and yttrium enhance the adhesion of the oxide layer on the floor. Galvanic corrosion (also known as “dissimilar-metallic corrosion”) refers to corrosion damage induced when two dissimilar supplies are coupled in a corrosive electrolyte. The commonest electrolyte is water, ranging from freshwater to seawater.

When it comes to stainless-steel, the lower the grade the better. The most common and expensive grade of steel is Type 304, which incorporates roughly 18 percent chromium and eight percent nickel. But the most popular and most cost-effective grade of metal is Type 430, which contains 17 p.c chromium and zero.12 % carbon. It’s the chromium that offers chrome steel its corrosion-resistant properties.

Is 304 stainless steel safe?

intervals such as happens when there is condensation, rain, fog or other moisture sources making contact. As an example, bolts and other connectors of different metals applied directly on stainless steel in a regularly wet environment can cause both metals to corrode and even fail at the connection point.

- Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault stainless-steel.

- Type 304, the most common grade of stainless-steel with 18% chromium, is resistant to roughly 870 °C (1,600 °F).

- Resistance to different gases relies on the type of gas, the temperature, and the alloying content of the stainless-steel.

- The minimal 10.5% chromium in stainless steels supplies resistance to roughly seven hundred °C (1,300 °F), while 16% chromium provides resistance as much as approximately 1,200 °C (2,200 °F).

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

As an austenitic stainless steel alloy, it has qualities such as excessive power, corrosion resistance, and excessive concentrations of chromium and nickel. The alloy has a tensile energy of 579 MPa (84 ksi) and a most use temperature of around 800˚C (1,472˚F).

What thickness is 18 gauge steel?

When using stainless steel cookware, know that deeply scratched and pitted pans can cause metals (nickel and chromium) to migrate into food in trace amounts. These are not toxic elements, so there is not really cause for concern unless you have a specific allergy or sensitivity.

four hundred sequence stainless (ie. martensitic stainless steel) is magnetic. Stainless metal containing extra nickel (310 and 316 grades) is more more likely to remain non-magnetic after chilly work. An increase of chromium content material improves the corrosion resistance of chrome steel. The addition of nickel is used to boost the final corrosion resistance required in more aggressive usage or circumstances. The presence of molybdenum (Mo) improves the localized corrosion resistance.

The melting point of chrome steel 304 is reached at temperatures ranging between 2,550 °F – 2,650 °F (1399 °C – 1454 °C). However, the nearer grade 304 stainless-steel reaches its melting point, the more tensile energy it loses. Grade 316 is a well-liked alloy of stainless-steel with a melting vary of 2,500 °F – 2,550 °F (1,371 °C – 1,399 °C).

Is 316 Stainless Steel Worth The Extra Cost Over 304?

That’s why the Type 304 chrome steel fuel grills are extra durable and may stand up to heat higher than the Type 430. In different words, a 304 will keep its shiny look over time and will be easier to scrub, according to ApplianceMagazine.com.

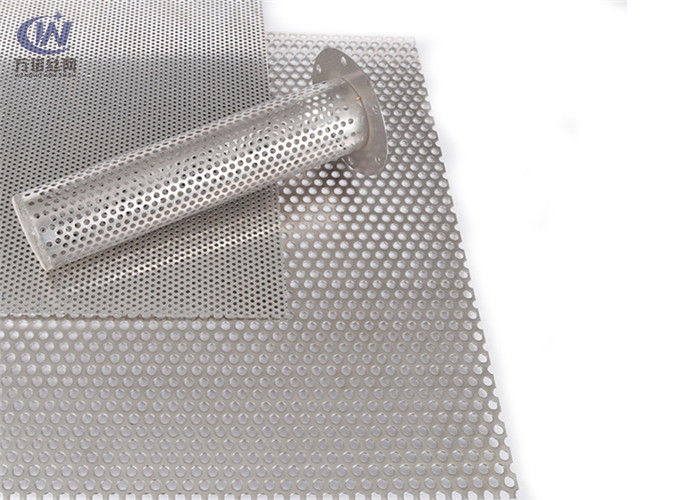

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean