Metals That Don’t Rust

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

As both 316 and 304 stainless steels are austenitic, when they cool, the iron remains within the form of austenite (gamma iron), a phase of iron which is nonmagnetic. The different phases of solid iron correspond to completely different crystal constructions. In different alloys of metal, this excessive-temperature phase of iron transforms to a magnetic phase when the metal cools. The presence of nickel in the stainless-steel alloys stabilizes austenite against this section transition because the alloy cools to room temperature. This corresponds to a considerably larger magnetic susceptibility than we would expect for different nonmagnetic supplies, however continues to be properly under what could be thought of magnetic.

Ferritic stainless steels, similar to 430 and CB-30 grades, are tougher, less ductile, and magnetic due to their predominately ferrite make-up. There are several families of stainless steels with totally different bodily properties. The magnetic properties of stainless steel are very depending on the elements added into the alloy. A primary stainless-steel has a ‘ferritic’ structure and is magnetic, shaped from the addition of chromium – it can be hardened through the addition of carbon, making it ‘martensitic’.

Stainless Steels

If a chrome steel is mostly comprised of an austenite structure, then it won’t be magnetic. The hottest stainless steel is Type 304, which accommodates approximately 18 percent chromium and eight % nickel. If the alloy is mechanically deformed, i.e. bent, at room temperature, it’s going to partially transform to the ferritic section and will be partly magnetic, or ferromagnetic, as it is more precisely termed.

Application:kitchware,door,decoration,elevator,water tank,etc

- The presence of nickel within the chrome steel alloys stabilizes austenite towards this section transition as the alloy cools to room temperature.

- As each 316 and 304 stainless steels are austenitic, when they cool, the iron stays within the type of austenite (gamma iron), a phase of iron which is nonmagnetic.

- The completely different phases of cast-iron correspond to different crystal buildings.

- In different alloys of steel, this excessive-temperature part of iron transforms to a magnetic part when the metal cools.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

By lowering or eliminating the amount of ferrite within the chemical composition, wrought material manufacturers are able to make an alloy that’s easier to roll into sheets or bars. Cast materials producers do not have the identical necessities and therefore, can use a barely tougher alloy that contains ferrite. While these metals don’t rust, that does not mean that they don’t corrode. They have their own forms of corrosion, such as pitting that can happen in stainless-steel or the blue-inexperienced tarnish found on oxidized copper. Furthermore, if they’re brought into contact with a carbon metal or different type of metal that does rust, iron deposits could be made on the floor of these supplies that will oxidize and create rust.

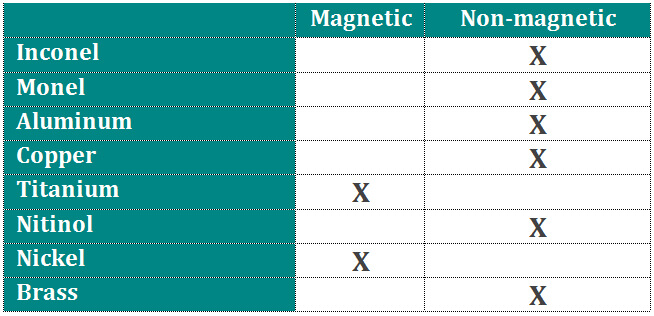

Since stainless steel is a kind of steel, there is an abundant quantity of iron in its make-up. Some individuals believe that stainless steel is a very non-magnetic material. Others consider that stainless steel should be magnetic because it incorporates iron. However, like with most issues, the reply lies someplace in between. The fact is, some forms of stainless steels are magnetic whereas others usually are not.

Ferritic stainless steels are typically magnetic as they have large portions of ferrite in their chemical composition. The combination of a ferritic crystal structure with iron makes ferritic stainless steels magnetic. However, some ferritic stainless steels may have a weaker magnetic pull than normal carbon metal. The terms “austenitic” and “ferritic” discuss with the crystalline structures. Austenitic (300 sequence) stainless steels, which are the commonest, have an austenitic crystalline structure and are softer, ductile, and in addition nonmagnetic.

If the atoms in the steel crystal are too extensively spaced, the trade effects are too small to cause alignment of the magnetic moments of neighboring atoms and the crystal won’t exhibit ferromagnetism. The requirement of a high density of states stems from the Pauli Exclusion Principle. This precept prohibits electrons with the same spin from occupying the identical energy degree. Consequently, if the density of electron states is comparatively small, electrons might want to occupy greater energy states to ensure that all to have the identical spin. If the rise in vitality ensuing from the occupancy of higher vitality levels exceeds the lower in vitality resulting from electron exchange power, the structure won’t be ferromagnetic.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean