Why Choice us All that You Need To Know About Us

What’s The Difference Between 304l And 316l Stainless Steel?

There is not any visible distinction between 304L and 316L stainless steel, both are polished or grained the exact same means, you differentiate between them just by taking a look at them. This is because of the fact that rust is iron oxide, and most aluminum has just about no iron in its composition. However, aluminum does oxidize, nevertheless it truly protects the underlying unoxidized aluminum. This is as a result of the aluminum oxide is extra corrosion resistant than the aluminum alloy it rests on. This is totally different than rust, as a result of rust will flake away from an iron alloy thus permitting the rusting course of to proceed until material failure.

Properties And Uses Of 316 And 316l Stainless Steel

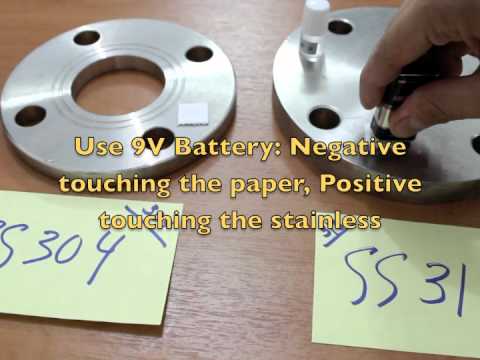

There’s no visible distinction between two equivalent items of sheet metal, a refined or grained the exact same way. That’s why you need a material check report (MTR) of the particular materials to validate it as being 304 or 316. Some small components similar to clamps and mounting feet, constructed of 316 stainless-steel are particularly marked, on this case a number 6 inside a circle, as shown within the picture above.

- Due to the temperatures created during the welding process (which may lead to carbon precipitation) – “L” grades are sometimes used.

- Quite commonly, Stainless mills provide these stainless grades as twin certified, similar to 304/304L or 316/316L.

- Carbon ranges are stored to .03% or underneath to keep away from carbide precipitation, which can lead to corrosion.

- Type 316 metal is an austenitic chromium-nickel chrome steel that accommodates between two and 3% molybdenum.

Applications For 316 Stainless Steel

However, 316 may be annealed to withstand weld decay. 316L also is a good stainless steel for top-temperature, excessive-corrosion uses, which is why it’s so well-liked for use in development and marine tasks.

How Do You Know You’re Getting 316 Stainless Steel Instead Of 304 Stainless Steel?

It is also used in pulp, paper, and textile processing equipment and for any parts exposed to marine environments. 316L, however, is a better choice for a project that requires plenty of welding as a result of 316 is more susceptible to weld decay than 316L (corrosion within the weld).

To sum it up, 316 metal is worth the expense if you want superior corrosion resistance and your utility A240 304L Stainless steel plate accommodates water. If not, 304 metal will serve your needs just fantastic.