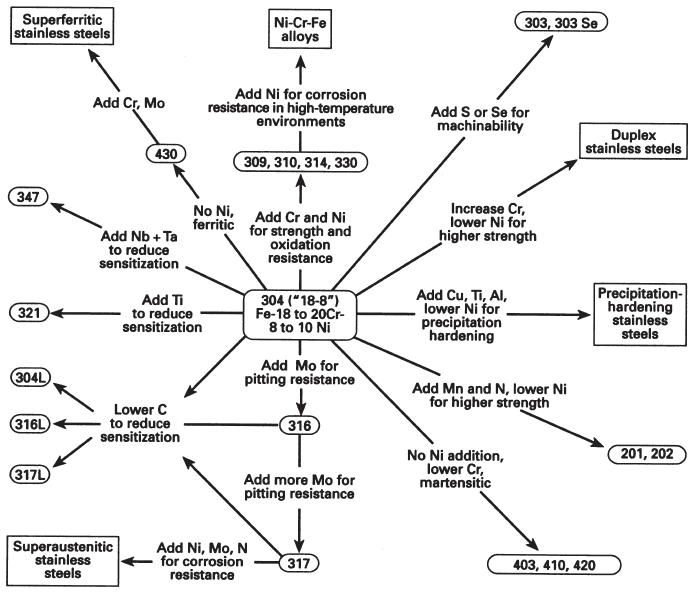

Our mainly stainless steel grade: ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

What’s The Difference Between Grade 304 And 304l Stainless Steel?

I am not sure of the exact makeup of the plate but the doctor stated it was chrome steel. I am hesitant to do that as a result of I don’t need to trigger any injury to the plate itself. I can try to get data on what sort of metal was used within the plate from the physician since I am guessing it isn’t pure metal. It appears an odd request however I am not in a position to make use of a lot in the best way of pain drugs.

Compare The Two Types Of Stainless Steel

Additionally, the melting level of grade 304 stainless steel is a bit greater than that of grade 316. The melting range of 316 is 2,500 °F – 2,550 °F (1,371 °C – 1,399 °C), roughly 50 to a hundred levels Fahrenheit decrease than the melting level of grade 304 stainless steel. Additionally, grade 316 has added molybdenum in its formulation, which improves the alloy’s resistance to acids, alkalis, and chloride pitting. It also A240 304L Stainless steel plate is utilized in pulp, paper, and textile processing equipment and for any components uncovered to marine environments. Type 316 grade stainless-steel is particularly efficient in acidic environments.

Differences Between 316 And 316l

- If you’re designing hypoallergenic earrings or other jewellery, what are your choices?

- Besides the rough setting of the sea and marine applications, chlorides, similar to salt, can eat away at even the toughest metals.

- The answers aren’t as simple as you would possibly hope, however there are some nice (and economical) decisions.

- Is surgical chrome steel the identical as hypoallergenic or nickel free?

This grade of metal is effective in defending against corrosion attributable to sulfuric, hydrochloric, acetic, formic, and tartaric acids, as well as acid sulfates and alkaline chlorides. While just like Type 304, which is frequent within the food business, each kind 316 and 316L exhibit better corrosion resistance and are stronger at elevated temperatures.

This permits 304L chrome steel to be used within the “as-welded” state, even in extreme corrosive environments. Grade 304L has a slight, but noticeable, reduction in key mechanical performance characteristics in comparison with the “commonplace” grade 304 stainless-steel alloy. This difference of 0.05% carbon content produces a slight, however marked, difference in the performances of the 2 alloys. There is no seen distinction between 304L and 316L stainless steel, both are polished or grained the very same way, you differentiate between them simply by taking a look at them. One of the benefits of many forms of metals is the fact that they are comparatively ductile; ductility ensures that metals bend before they break.

They also are both non-hardenable by warmth treatment and can be readily formed and drawn (pulled or pushed through a die or smaller hole). A summary sheet evaluating key traits of generally used chrome steel alloys. Marlin Steel is a leading manufacturer of custom‐engineered products from steel wire and sheet steel. Its industrial materials handling containers serve many industries including aerospace, defense, medical and automotive. The answer is that the 304L alloy’s lower carbon content helps reduce/eliminate carbide precipitation through the welding course of.

Over eighty locations in North America providing prompt access to a wide variety of metal sorts, shapes, sizes and grades. A friend instructed I soak my foot in some hydrogen peroxide and water, a very low concentration of peroxide of course.