Why Choice us All that You Need To Know About Us

, 2nd And Ba Cold Rolled Finishes

Ra and RMS are both representations of surface roughness, however every is calculated in a different way. Ra is calculated because the Roughness Average of a surfaces measured microscopic peaks and valleys. RMS is calculated because the Root Mean Square of a surfaces measured microscopic peaks and valleys.

What Is A 2b Finish On Stainless Steel?

Each worth uses the same individual height measurements of the surfaces peaks and valleys, but makes use of the measurements in a different method. One can infer from examination of the formulation, that a single giant peak or flaw inside the microscopic surface texture will effect (increase) the RMS worth greater than the Ra worth. A No. 7 end has a mirror-like look with a high degree of reflectivity. It is a buffed finish achieved by progressively utilizing finer and finer abrasives, finishing with Buffing compounds.

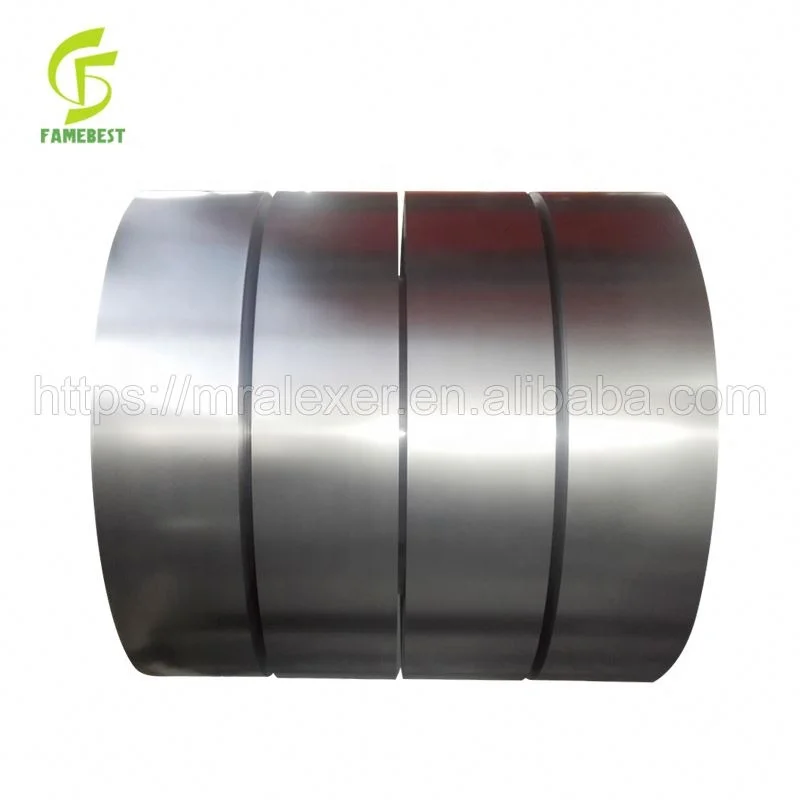

- A brilliant, smooth mirror-like end typically produced by cold rolling adopted by annealing in a protective environment so as to prevent oxidation and scaling throughout annealing.

- A 2b Mill end is achieved via the addition of a lightweight cold roll move.

- This is probably the most utilized stainless-steel finish on the planet and it’s the typical finish for a lot of grades together with 304 stainless steel.

Stainless Steel: What, Where, Why Of Austenitic Grades

A No. 1 finish could comprise shiny spots were surface imperfections had been removed by grinding. It is mostly used in industrial purposes, similar to equipment for elevated temperature service. Pickling is the removal of excessive temperature scale and the adjacent low chromium layer of steel A240 304L Stainless steel plate from the surface of chrome steel by chemical means. Pickling may even take away manganese sulphide inclusions and some other contamination on the floor. Pickling leads to a very clear, extremely corrosion resistant floor, however will barely roughen the floor.

Finishes

The upside to a satin end stainless steel balustrade is that the surface is not reflective implies that a small amount of filth or oil will go largely undetected. In other phrases, you gained’t have to wipe it down as typically as a mirror polish balustrade.

This is completed by a heat therapy that produces a uniform microstructure (annealing) and ensures that the stainless-steel will meet mechanical property necessities. The resulting floor accommodates a darkish non-uniform look the place floor chromium has been lost, and the expected level of corrosion resistance has been achieved.