Our mainly stainless steel grade: ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

What’s The Difference Between 304l And 316l Stainless Steel?

What manufacturing techniques are used for surgical metal jewellery? Do you could have any referrals that would be helpful for mass manufacturing of this product line? I’m going to construct the prototypes in base metallic for workability properties.

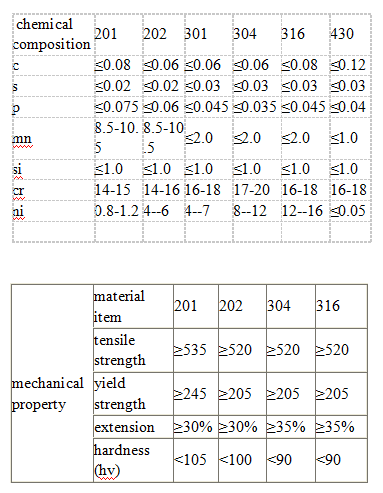

The Mechanical Difference

I am in negotiations with some purchasers who need to produce a physique jewellery line. Most of this product falls into the stainless/surgical steel category and I am less than familiar with such manufacturing techniques. I do have thirteen years of watch repair experience so I am familiar with refinishing and laser welding techniques for stainless-steel. Terms of manufacturing that I am familiar with are referred to as Dye striking, Casting, electroplating, electroforming, fabrication, drawing/pulling, forging, Ext.

Qualities Shared By 316 And 316l

- This reduces pitting from chemical environments and permits grade 316 chrome steel for use in extremely acidic and caustic environments that may in any other case eat away at the steel.

- For occasion, grade 316 stainless-steel can stand up to caustic options and corrosive functions corresponding to vapor degreasing or many other components cleansing processes.

- The increased nickel content material and the inclusion of molybdenum makes grade 316 chrome steel a bit costlier than grade 304 per ounce of fabric.

Stainless steel is an ideal corrosion-resistant material, there are variant grades of stainless-steel, the most typical chrome steel grades are 304L and 316L. Rust compromises the mechanical traits of metallic, alters the chemical properties, and is (usually) not considered aesthetically pleasing. It is for these causes that many people in command of design and material selection try to keep away from having to cope with rust and the negative effects that come with it. One way to get rid of the threat of rust is to make use of metals that don’t rust.

Qualities Of Type 316l Steel

I by no means really tried bronze or copper, they appear suspicious, as in I would get a response. Stainless steel is specifically designed to avoid tarnish and other floor discoloration — Nickel is actually added to chrome steel to help with this course of. So a stainless-steel (nickel-free or not) may work well for her.

There is quite a lot of several types of 316 chrome steel. Each is barely completely different, and every is used for various purposes. The “L” designation means 316L metal has less carbon than 316. From a chemical point of A240 304L Stainless steel plate view, 304 stainless-steel contains 18% chromium and eight% nickel whereas 316 stainless-steel incorporates 16% chromium, 10% nickel and a couple of% molybdenum.

(itchy rashes) Silver and even stainless silver I can get a slight response after forty five min. of use. Stainless steel I can get a reaction after about 6 hours of use.